Popular Products

-

Water Restoration Technician (WRT) – April 23-25

$399.00 -

Serum Systems Free Training May 22

Call for Price 1-800-435-5868 -

Applied Microbial Remediation Technician (AMRT)- IN PERSON March 18-21 2024

$950.00 -

Benefect Decon 30 Disinfectant

$34.99 – $139.99 -

Trauma and Crime Scene Technician (TCST) April 23-25

$499.00 -

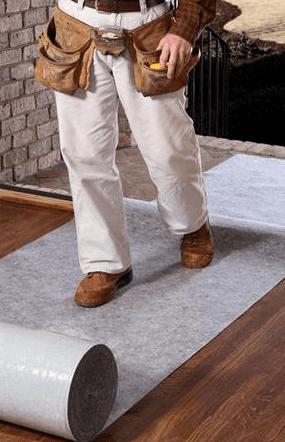

Clean & Safe Pro Floor Protection 32”x100′

$119.00 -

CLO2 102g Gas Release Packet/Complete Kit

$59.95 -

CLO2 52g Gas Release Packet/Complete Kit

$39.95 -

ProLiminator Sunshine

$30.00 -

MultiPhase Deodorizer Gal.

$34.40 -

Grease Magic Rinse + 1 Gal.

$21.99 -

Benefect Disinfectant Gallon

$48.99 – $176.36